Polished Concrete Levels:

Depending on the diamond grit we use to polish a concrete floor, we can achieve different ranges of aggregate exposure and different levels of sheen, from matte to a glassy mirror-like finish. The Concrete Polishing Association of America classifies finished gloss levels in ranges from 1 through 4 and aggregate exposures as A, B, C or D, depending on the degree of exposure. For coarse grinding, we will generally start out using diamonds embedded in a metal matrix. As we begin to polish the floor in successive passes, we will typically switch to finer diamond abrasives bonded in a plastic or resinous matrix to achieve higher degrees of shine. Here are the four levels of polishing and the degree of shine you can expect to achieve at each level. (Source: Bob Harris' Guide to Polished Concrete)

Level 1 (flat)

A level 1 ground polish usually can be obtained by stopping below the 100-grit resin bond. When you look directly down at the floor, it will appear somewhat hazy with little if any clarity or

reflection.

Level 2 (satin)

A level 2 honed polish is obtained by stopping at the 400-grit resin bond, producing a low-sheen finish. When you look directly down at the finished floor and at a distance of roughly 100 feet, you

can start to see a slight overhead reflection. This grit level produces a low-luster matte finish.

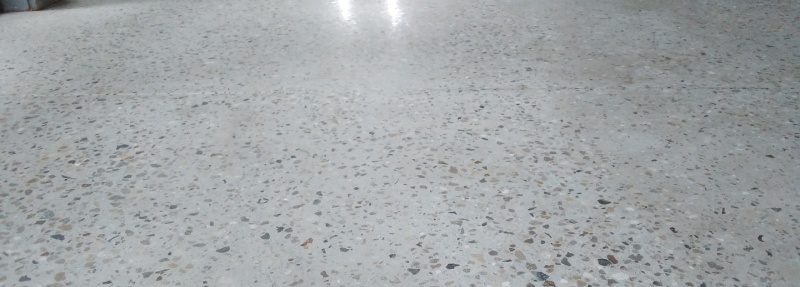

Level 3 (semi-polished)

A level 3 polish is achieved by going up to an 800-grit or higher diamond abrasive. The surface will have a much higher sheen than that of level 2 finish, and you'll start to see good light

reflectivity. At a distance of 30 to 50 feet, the floor will clearly reflect side and overhead lighting.

Level 4 (highly polished)

This level of polish produces a high degree of shine, so that when standing directly over the surface, you can see your reflection with total clarity. Also, the floor appears to be wet when viewed

from different vantage points. A level 4 polish is obtained by going up to a 3,000-grit resin-bond diamond or by burnishing the floor with a high-speed burnisher outfitted with specialty buffing

pads. We can do both.

At a level 3 polish, your concrete floors will really begin to shine and clearly reflect side and overhead lighting.

Depending on the diamond grit we use to polish a concrete floor, we can achieve different ranges of aggregate exposure and different levels of sheen, from matte to a glassy mirror-like finish. The Concrete Polishing Association of America classifies finished gloss levels in ranges from 1 through 4 and aggregate exposures as A, B, C or D, depending on the degree of exposure. For coarse grinding, we will generally start out using diamonds embedded in a metal matrix. As we begin to polish the floor in successive passes, we will typically switch to finer diamond abrasives bonded in a plastic or resinous matrix to achieve higher degrees of shine. Here are the four levels of polishing and the degree of shine you can expect us to achieve at each level.

GLOSS LEVEL TABLE

| LEVEL | GRIT | SHEEN LEVEL | MINIMUM NO. OF ABRASIVE PASSES | APPEARANCE | GLOSS READING |

|---|---|---|---|---|---|

| 1 | Below 100 | None to very low | 4 | Flat. Floor has little if any reflectivity. | n/a |

| 2 | 100 to 400 | Low to medium | 5 | Satin or matte appearance with or without slight diffused reflection. | 40-50 |

| 3 | 800 and higher | Medium to high | 6 | Semi-polished. Objects being reflected are not quite sharp and crisp, but can be easily identified. | 50-60 |

| 4 | 1,000 and higher | High | 7 | Highly polished. Objects being reflected are sharp and crisp, with mirror-like clarity. | 60-80 |

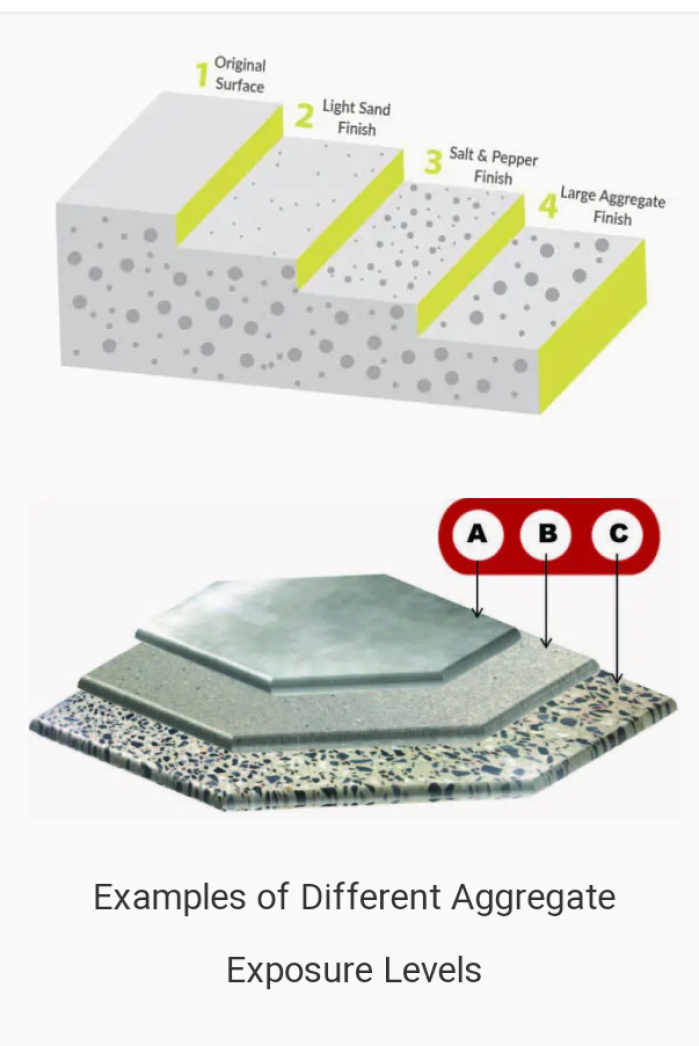

Aggregate exposure

Aggregate exposures range from “cream,” with very little exposure (Class A), to large aggregate exposure up to ¼ inch (Class D). Because there is very little cut depth, a cream exposure will not

remove existing blemishes or surface imperfections in the concrete. A Class D aggregate exposure is very attractive, but requires more aggressive grinding, which can increase the cost of the project

and expose pits or divots in the concrete that will need to be filled. Note that varying degrees of sand and aggregate exposure, not to mention small pits and divots in the surface, can significantly

influence gloss readings.

AGGREGATE EXPOSURE TABLE

| CLASS | NAME | APPROXIMATE SURFACE CUT DEPTH | APPEARANCE |

|---|---|---|---|

| A | Cream | Very little | Little aggregate exposure. |

| B | Fine aggregate (salt and pepper finish) | 1/16 inch | Fine aggregate exposure with little or no medium aggregate at random locations. |

| C | Medium aggregate | 1/8 inch | Medium aggregate exposure with little or no large aggregate exposure at random locations. |

| D | Large aggregate | 1/4 inch | Large aggregate with little or no fine aggregate exposure. |

Polished Concrete Cost:

Economical:

You can expect to pay between $3 and $12 per square foot for polished concrete, depending on your location and the complexity of the project. Polished concrete pricing is basically dependent upon how many levels of grinding will be required to get the floor to a suitably smooth surface. The cost for polished concrete can go up from there depending upon any decorative effects that are applied such as staining or scoring, etc.

Polished concrete cost tends to be more economical with large spaces. Residential floors tend to be a bit higher in price because of the requirement for smaller equipment and for getting into smaller spaces.

There are different price points for various levels and designs for polished concrete.

$3-$7/sq ft is the price for commercial floors.

$6-$12/ sq ft is the typical cost for polished concrete in a residential floor because it is more difficult to get a consistent look using a smaller machine.